To choose the best vacuum oven, consider the temperature range and chamber size. Evaluate the vacuum level and control features.

Selecting the best vacuum oven involves understanding your specific needs and application requirements. Vacuum ovens are essential for drying, curing, and processing sensitive materials. They offer precise temperature control and a reduced-pressure environment, which helps preserve the integrity of the materials.

Consider the temperature range that your tasks demand. A wide temperature range ensures versatility. Chamber size is crucial for accommodating various sample volumes. Look for ovens with digital controls for accuracy and ease of use. High-quality vacuum pumps enhance performance. Reliable safety features, such as over-temperature protection, are vital. Choose a vacuum oven that balances your budget with your technical needs.

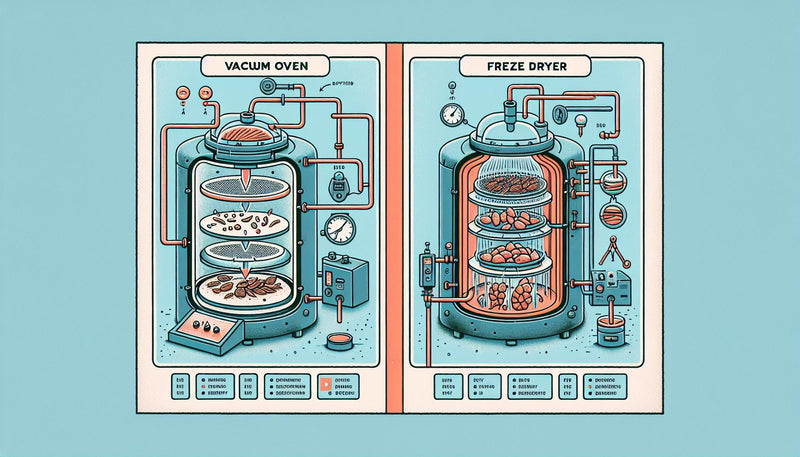

Credit: www.scisolinc.com

Introduction To Vacuum Ovens

Vacuum ovens are essential tools in many industries. These ovens are designed to remove moisture, gas, and other contaminants from materials. They operate under reduced pressure, which speeds up the drying process. This makes them highly efficient and versatile.

Purpose In Various Industries

Vacuum ovens are used in a variety of fields. They are common in the pharmaceutical, food processing, and electronics industries. In pharmaceuticals, they help in drying sensitive drugs. In food processing, they preserve the flavor and nutrients of food. Electronics use vacuum ovens to dry components without causing damage.

Advantages Over Conventional Ovens

Vacuum ovens offer several benefits over traditional ovens. One major advantage is faster drying times. The reduced pressure allows for quicker moisture removal. This saves time and energy.

Another benefit is uniform drying. Conventional ovens can have hot spots, but vacuum ovens ensure even heat distribution. This results in consistent drying or baking of materials.

Vacuum ovens also operate at lower temperatures. This is ideal for heat-sensitive materials. Lower temperatures prevent thermal degradation, preserving the quality of the material.

Here are some key advantages in a table format:

| Feature | Vacuum Oven | Conventional Oven |

|---|---|---|

| Drying Time | Fast | Slow |

| Heat Distribution | Uniform | Uneven |

| Operating Temperature | Low | High |

| Energy Efficiency | High | Low |

In summary, vacuum ovens are more efficient and versatile. They offer faster, uniform, and low-temperature drying. These benefits make them invaluable in many industries.

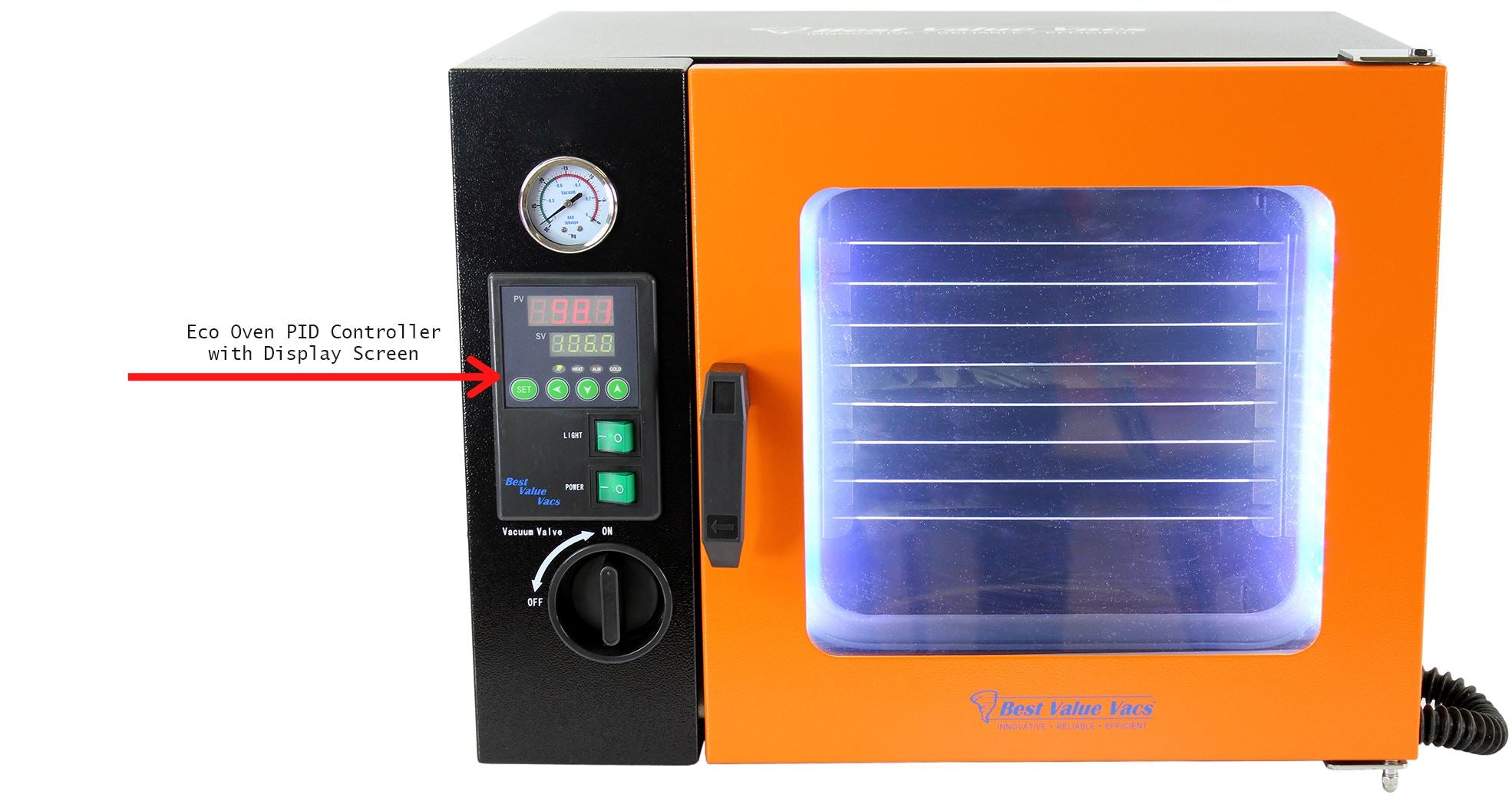

Credit: shopbvv.com

Key Features To Consider

Choosing the best vacuum oven can be challenging. Several key features determine the performance and efficiency of a vacuum oven. This section will cover the most important aspects to consider.

Temperature Range And Stability

The temperature range of a vacuum oven is crucial. It determines the types of experiments and processes you can conduct. A wide temperature range allows for more flexibility. Look for ovens with a stable temperature to ensure consistent results. Stability is essential for repeatable outcomes.

A table summarizing temperature ranges:

| Temperature Range | Application |

|---|---|

| Room Temperature to 200°C | Basic drying and heating |

| 200°C to 400°C | Advanced research and material testing |

Chamber Size And Material

The chamber size affects the volume of samples you can process. Choose a size that fits your needs. Larger chambers are better for bulk processing. Smaller chambers are ideal for limited space or fewer samples.

The material of the chamber is also vital. Stainless steel chambers are durable and easy to clean. Aluminum chambers offer excellent heat distribution but may be less durable.

- Stainless Steel: Durable, easy to clean

- Aluminum: Excellent heat distribution

Heating Rate And Distribution

A fast heating rate can save you time. It is beneficial for quick processes. Ensure the oven has an even heat distribution. Uneven heating can cause inconsistent results. Forced air circulation can help in achieving uniform heat.

- Fast heating rate for time efficiency

- Even heat distribution for consistent results

By considering these features, you can choose the best vacuum oven. Make sure it meets your specific needs and preferences.

Types Of Vacuum Ovens

Choosing the best vacuum oven can be confusing. There are different types to consider. Each type serves unique needs and applications. This section covers the main types of vacuum ovens.

Standard Benchtop Models

Standard benchtop models are small and compact. They fit easily on lab benches. These models are ideal for small-scale work. They are easy to use and maintain. Most have digital controls and safety features.

- Compact size – Fits on lab benches

- Easy to use – User-friendly controls

- Safety features – Built-in protection

Benchtop models are perfect for labs with limited space. They offer reliable performance. They are also more affordable compared to larger units.

Large Industrial Units

Large industrial units are designed for heavy-duty tasks. They are used in big factories and research labs. These units handle large volumes of materials. They offer advanced features and higher capacity.

- High capacity – Handles large volumes

- Advanced features – Sophisticated control systems

- Durable – Built for heavy-duty tasks

Industrial units are suitable for large-scale production. They provide precise temperature control. They also ensure consistent results for complex processes.

| Feature | Benchtop Models | Industrial Units |

|---|---|---|

| Size | Compact | Large |

| Capacity | Low | High |

| Usage | Small-scale | Large-scale |

| Cost | Affordable | Expensive |

Understanding the types of vacuum ovens helps in making the right choice. Consider your needs and budget. Select the model that fits your requirements best.

Vacuum Oven Applications

Vacuum ovens are vital in various industries. They offer precise temperature control and uniform heat distribution. These features make them indispensable for many applications. Let’s explore how vacuum ovens are used in different sectors.

Electronics And Aerospace

In the electronics industry, vacuum ovens are essential for removing moisture. They ensure that components are dry and free from contaminants. This process enhances the longevity and performance of electronic devices.

Vacuum ovens are also used for outgassing. Outgassing removes volatile substances from materials. This is crucial in manufacturing semiconductors and circuit boards. Vacuum ovens create a controlled environment for this process.

In the aerospace sector, vacuum ovens are used for curing composite materials. These materials are used in aircraft and spacecraft. Curing in a vacuum oven ensures that the materials are strong and lightweight. This process is vital for safety and efficiency in aerospace applications.

Medical And Pharmaceutical

The medical industry relies on vacuum ovens for sterilization. Medical instruments must be free from bacteria and viruses. Vacuum ovens achieve this by using high temperatures in a controlled environment.

In the pharmaceutical industry, vacuum ovens are used for drying and curing drugs. They remove moisture without damaging sensitive compounds. This ensures the drugs are effective and safe for consumption.

Vacuum ovens also help in lyophilization, or freeze-drying. This process preserves biological samples and medications. It extends their shelf life and maintains their quality.

| Industry | Application |

|---|---|

| Electronics | Moisture Removal, Outgassing |

| Aerospace | Composite Material Curing |

| Medical | Sterilization |

| Pharmaceutical | Drug Drying, Lyophilization |

Choosing the best vacuum oven depends on your specific needs. Consider the applications and features that matter most to your industry.

Evaluating Brand And Manufacturer

Choosing the best vacuum oven requires evaluating the brand and manufacturer. This ensures you invest in a reliable and durable product. Let’s explore crucial factors like reputation, reviews, after-sales support, and warranty.

Reputation And Reviews

Reputation is vital when selecting a vacuum oven. A well-known brand often signals quality and trust. Check customer reviews on various platforms. Positive feedback indicates satisfied users. Look for consistent praise on performance and durability. Avoid brands with frequent complaints.

Visit forums and social media for real user experiences. This offers insights into common issues and benefits. Expert reviews can also guide your decision. They provide detailed analysis and comparisons.

After-sales Support And Warranty

Good after-sales support is essential. It ensures help when problems arise. Look for brands with dedicated customer service teams. Responsive support can save time and stress. Check if the brand offers online resources and manuals.

Warranty is another critical factor. A longer warranty period shows confidence in the product. Ensure the warranty covers essential parts and services. Read the warranty terms carefully. This helps avoid unexpected costs later.

| Brand | Reputation | Warranty Period | Customer Support |

|---|---|---|---|

| Brand A | High | 2 Years | 24/7 Support |

| Brand B | Medium | 1 Year | Office Hours Support |

| Brand C | Low | 6 Months | Email Support |

Use this table to compare brands at a glance. It helps make an informed decision. Investing in a reliable brand ensures long-term satisfaction. Always choose brands with good reputation and strong support.

Safety Features And Protocols

Choosing the best vacuum oven involves understanding its safety features. These features ensure the oven operates safely and efficiently. Below are key safety aspects to consider.

Temperature Control Mechanisms

Temperature control is crucial for a vacuum oven. It ensures materials are heated correctly and safely.

- Digital Controls: Most ovens have digital controls for precise settings.

- Overheat Protection: This feature prevents the oven from overheating.

- Temperature Alarms: Alerts you if the temperature exceeds safe levels.

Pressure Safety Measures

Pressure safety measures protect both the user and the equipment. Proper pressure management is essential for safe operation.

- Pressure Gauges: Monitors the internal pressure of the oven.

- Relief Valves: Automatically releases pressure if it exceeds safe limits.

- Sealed Doors: Ensures no air leakage, maintaining safe pressure levels.

| Feature | Description |

|---|---|

| Digital Controls | Allows precise temperature settings. |

| Overheat Protection | Prevents the oven from overheating. |

| Temperature Alarms | Alerts if the temperature is too high. |

| Pressure Gauges | Monitors internal pressure levels. |

| Relief Valves | Releases excess pressure safely. |

| Sealed Doors | Prevents air leaks and maintains pressure. |

Understanding these safety features is crucial. They ensure the vacuum oven operates safely and efficiently.

Price Vs. Performance

Choosing the best vacuum oven requires balancing price and performance. An expensive oven might not always be the best. It’s crucial to consider both initial investment and ongoing operating costs. This guide will help you make an informed decision.

Initial Investment

The initial investment in a vacuum oven can vary widely. Prices depend on the oven’s brand, size, and features. Here are some key factors to consider:

- Brand: Reputable brands often come with a higher price tag but offer better reliability.

- Size: Larger ovens can handle more material, but they cost more.

- Features: Advanced features like programmable controls increase the price.

Below is a table summarizing typical price ranges based on these factors:

| Feature | Price Range |

|---|---|

| Basic Models | $500 – $1,000 |

| Mid-Range Models | $1,000 – $3,000 |

| High-End Models | $3,000 – $10,000 |

Operating Costs

Operating costs are another important factor. These include energy consumption, maintenance, and replacement parts.

- Energy Consumption: More efficient models save money over time. Look for energy-efficient ratings.

- Maintenance: Regular maintenance ensures the oven runs smoothly. Factor in the cost of maintenance services.

- Replacement Parts: Some ovens require expensive parts. Check the availability and cost of replacement parts before buying.

To summarize, both initial investment and operating costs must be considered. Choose a vacuum oven that offers the best balance between price and performance. This ensures long-term satisfaction and value for your money.

Additional Considerations

Choosing the best vacuum oven involves more than just basic features. Considering additional factors can ensure you get the most out of your purchase. Here are some key considerations to keep in mind.

Ease Of Use And Maintenance

Ease of use is crucial for efficient operations. A vacuum oven should have a user-friendly interface. Clear controls and a readable display make operations smoother.

Maintenance is another important aspect. Look for easy-to-clean designs. Removable parts should be simple to detach and reassemble. This reduces downtime and keeps your oven in top condition.

Check for available support and warranty options. A reliable support system can solve issues quickly. Warranties provide peace of mind and protect your investment.

Accessories And Upgrades

Accessories can enhance the functionality of your vacuum oven. Consider shelves, trays, and vacuum pumps. These can make your tasks easier and more efficient.

Look for upgrade options. These can extend the lifespan of your oven. Software updates and additional features can improve performance over time.

Here’s a quick overview of useful accessories and upgrades:

| Accessory | Benefit |

|---|---|

| Shelves | Increase load capacity |

| Trays | Organize samples |

| Vacuum Pumps | Improve vacuum efficiency |

| Software Updates | Enhance functionality |

Choosing the right accessories and upgrades can significantly enhance the performance and efficiency of your vacuum oven.

Credit: www.ebay.com

Frequently Asked Questions

How To Choose A Laboratory Oven?

Consider temperature range, size, and uniformity. Check for safety features and energy efficiency. Ensure it meets specific application needs.

What Is The Vacuum Level Of A Vacuum Oven?

A vacuum oven typically achieves a vacuum level of 0. 1 to 0. 5 Torr. This range ensures optimal drying and processing.

What Is The Difference Between A Vacuum Oven And An Air Circulating Oven?

A vacuum oven removes air to lower the boiling point, ideal for delicate drying. An air circulating oven uses fans to circulate hot air, providing uniform heat.

When To Use A Vacuum Oven?

Use a vacuum oven for drying heat-sensitive materials, removing solvents, or achieving precise temperature control. Ideal for pharmaceuticals, electronics, and chemical labs.

Conclusion

Choosing the best vacuum oven doesn’t have to be hard. Focus on quality, features, and your specific needs. Research thoroughly and read reviews. The right vacuum oven will enhance your lab’s efficiency. Make an informed decision and invest wisely for long-term benefits.

Best Vacuum Oven: Top 10 Models for Efficient Purging and Heating